Ventilation

Energy efficiency class 1 according to the dual classification scheme based on the seasonal energy efficiency ratio (SEER) during cooling and heating operation. Power saving up to 26% in the entire SEER range.

This solution is suitable for conventional indoor use, as well as special process and sanitary conditions, cooling only operation, low temperatures and extreme heat, etc. The unit supports a full range of alternative applications.

Up to 16 fixed-speed modules (YH\YHE) and variable-speed inverter modules can be freely combined. This allows meeting various project demands, such as energy saving.

The heat exchanger is made of two U-shaped parts, with 45% more area on the air side and uniform all-round air return.

The unit is driven by a BLDC motor, while the control program with 8,000 counts per second and double filtering prevents power outages at any frequency level.

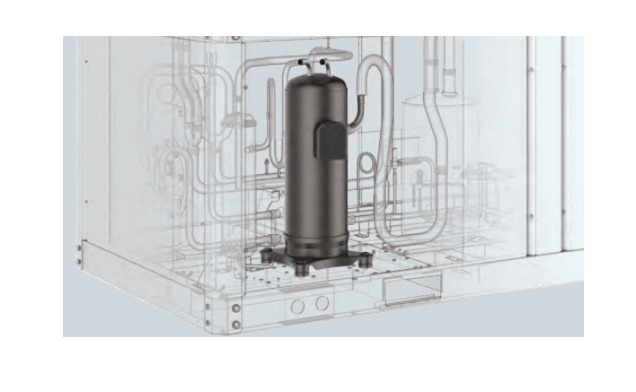

The powerful inverter compressor supports stepless adjustment of capacity within 15% to 100%. It also performs well under partial load, avoiding frequent starts and stops. The use of EVI technology enables operation in extreme cold or heat.

Partial load takes priority during operation. When several units operate together, each compressor is frequency controlled through intelligent management, which ensures balanced operation in the energy-efficient area of the performance curve.

- The heat pump components are completely concealed to prevent them from damaging

- Improved heat exchange efficiency thanks to the increased air intake area

- Sheet metal casing painted in ivory colour

- Distinctive inverter design with the technology of enhanced vapour injection (EVI)

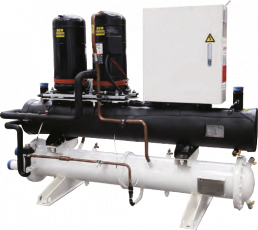

- High-efficiency shell-and-tube heat exchanger

- Modular design for easy combination of the units

- Easy to use touch control panel (accessory)

- Support of remote control via MODBUS

When multiple modules are combined, the frequency of each compressor is intelligently controlled, with priority given to the operation in an energy-efficient partial load area. At the same time, compressor running time and load are balanced to facilitate uniform wear of each module compressor.

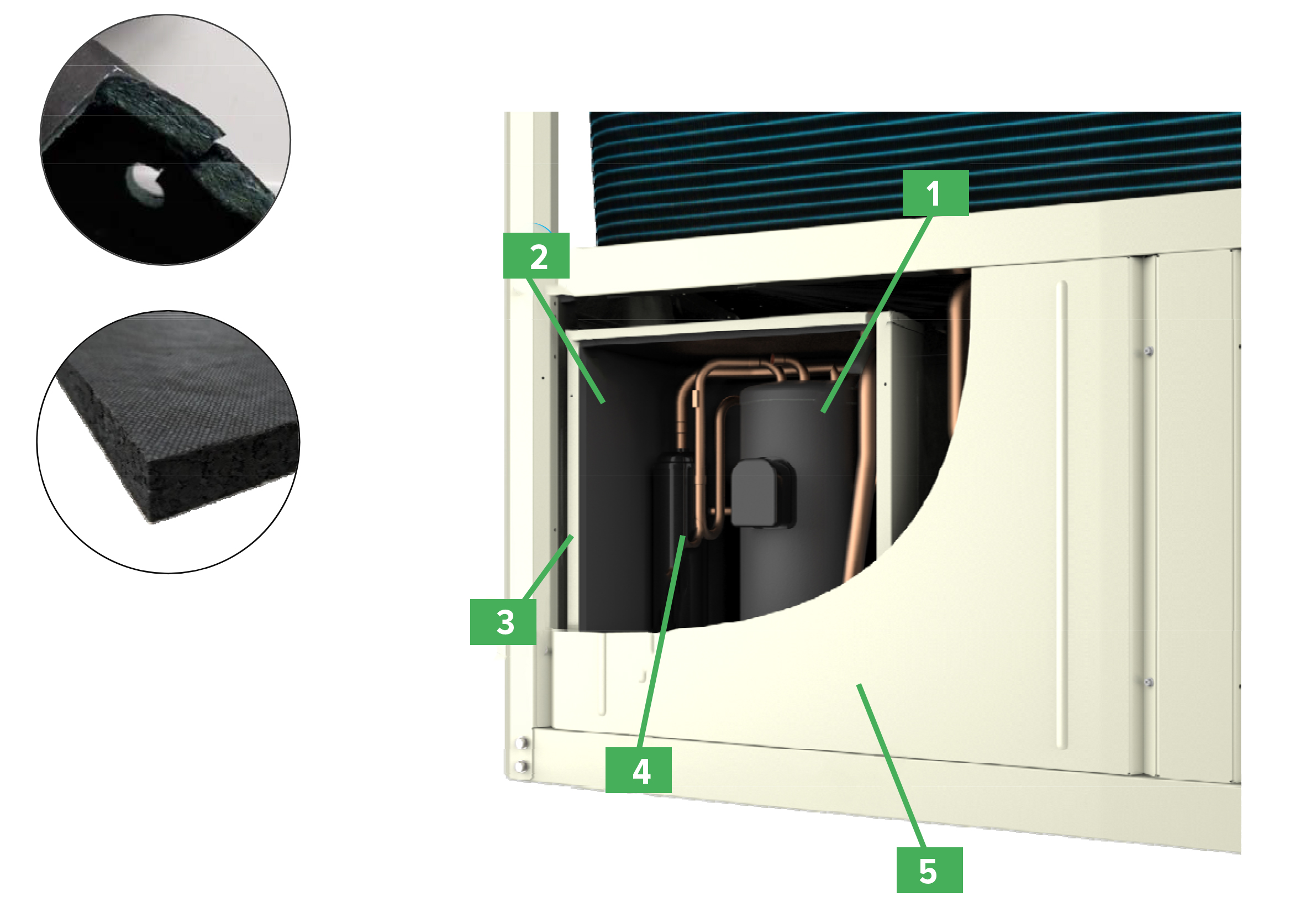

- Acoustic block. Green felt with butyl rubber material to frequency noises

- Ultra-silence acoustic panel absorber. High-density foaming damping material to effectively absorb vibration and noise across frequencies

- Hermetic soundproof box

- Suction and discharge copper pipe, oil separator, silencer, etc., placed in the compressor soundproof box

- Protection panel around the unit to further block noise

Sawtooth large impeller, low rotating speed, low fan speed, operating noise in low speed for dual blower as 30 dB. The brushless full DC fan motor features stepless speed adjustment of 15-100% and more stable operation, achieving higher energy efficiency while reducing noises.

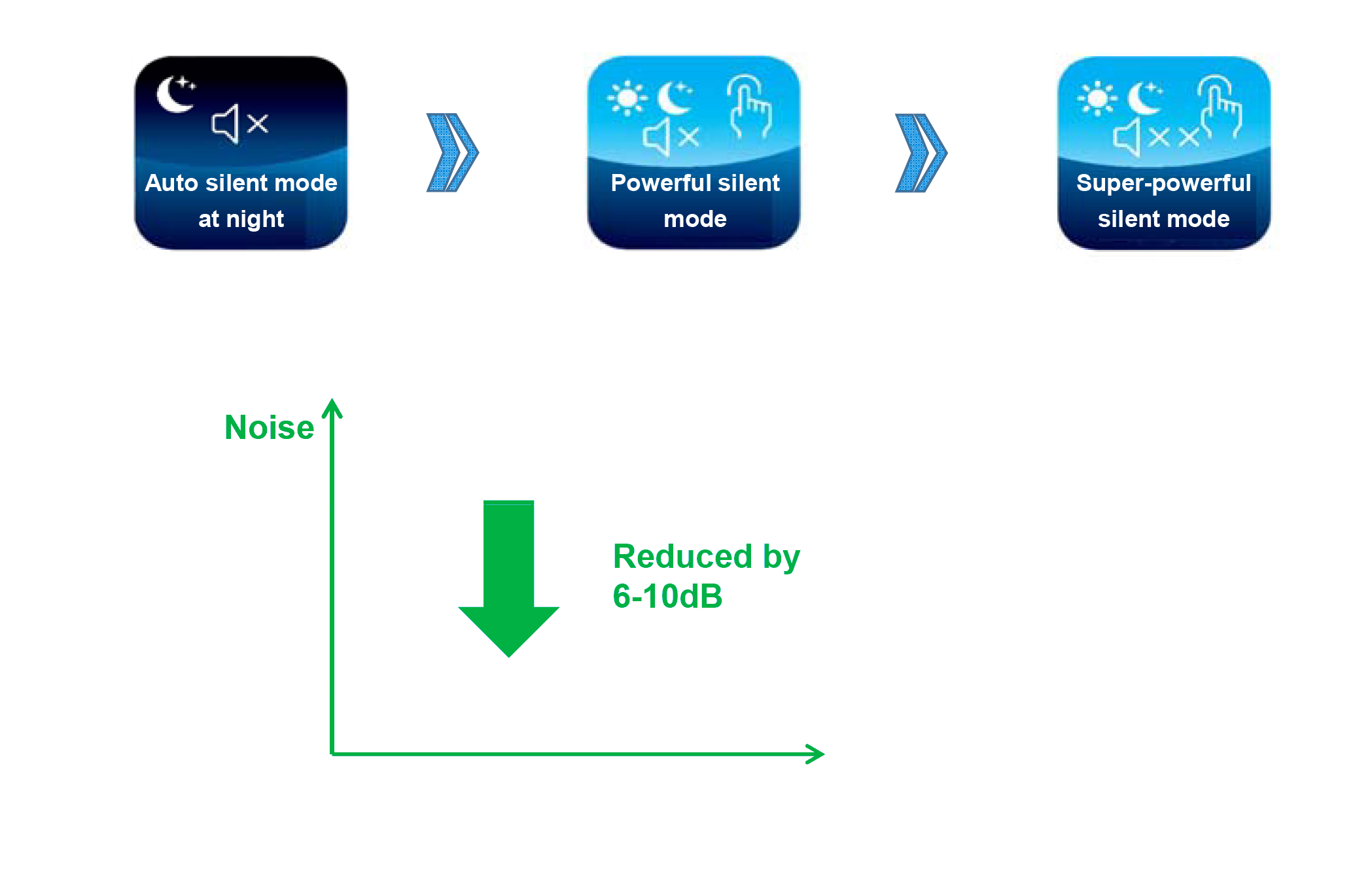

Three silent modes selectable

With wired controller settings, the unit automatically limits the operation frequency of the compressor and the fan and actively reduces noise to meet customers' higher requirements.

Thanks to many years of experience in the development and design of refrigeration equipment, the company has successfully implemented the technology enhaced vapour injection (EVI) and inverter technology and made a breakthrough in the operation of modular heat pumps, the operating range is increased.

| Specifications | Units | MCU035YHI | MCU065YHI | MCU130YHI |

| Rated cooling mode | ||||

| Cooling capacity | kW | 33,5 | 65,0 | 130 |

| Power consumption | kW | 12,0 | 21,2 | 41,8 |

| EER | W/W | 2,79 | 3,06 | 3,11 |

| Seasonal energy efficiency ratio (SEER) | W/W | 4,60 | 4,55 | 4,55 |

| Seasonal coeficient of perfomance (SCOP) | W/W | 3,20 | 3,10 | 3,10 |

| Rated heating mode | ||||

| Heating capacity | kW | 34,0 | 75,0 | 150 |

| Power consumption | kW | 10,5 | 23,4 | 45,0 |

|

COP Seasonal coeficient of perfomance (SCOP) |

W/W W/W |

3,24 3,20 |

3,20 3,10 |

3,33 3,10 |

| Power supply | 380 V, 3 phases, 50 Hz | 380 V, 3 phases, 50 Hz | 380 V, 3 phases, 50 Hz | |

| Water flow rate | m3/h | 5,76 | 11,2 | 22,4 |

| Water perssure drop | kPa | 30 | 45 | 45 |

| Type of water inlet/outlet pipe connection | DN40 external thread | DN 65 flange connection | DN65 flange connection | |

| Operation mode | Automatic microcontroller-based operation | Automatic microcontroller-based operation | Automatic microcontroller-based operation | |

| Compressor type | Inverter scroll compressor with enhanced vapour injection (EVI) | Inverter scroll compressor with enhanced vapour injection (EVI) | Inverter scroll compressor with enhanced vapour injection (EVI) | |

| Number of compressors | pcs. | 1 | 1 | 2 |

| Fan type | Low-noise inverter axial fan | Low-noise inverter axial fan | Low-noise inverter axial fan | |

| Number of fans | pcs. | 1 | 2 | 2 |

| Air flow rate | m3/h | 13000 | 26000 | 47000 |

| Refrigerant type | R410A | R410A | R410A | |

| Dimensions, LxWxH | mm | 1170×846×1694 | 2000×950×2020 | 2250x1150x2260 |

| Net weight | kg | 285 | 600 | 960 |

| Operating weight | kg | 300 | 660 | 1060 |

| Noise level | dB(A) | 50 – 61 | 50 – 67 | 50 – 67 |

| Maximum total electric power | kW | 20 | 31,5 | 63 |

| Maximum operating current | A | 30,5 | 50 | 100 |

Notes:

1. Rated cooling capacity and rated power consumption during cooling have been tested at the rated water flow rate, outlet water temperature 7 °C and ambient temperature 35 °C (dry bulb).

2.Rated heating capacity has been tested at the rated water flow rate, outlet water temperature 45 °C and ambient air temperature 7 °C (dry bulb) / 6 °C (wet bulb).